SKF helps increase horizontal grinding mill performance

Best in class is not an unachievable concept when it comes to horizontal grinding mill performance the most critical asset of a hard rock mining operation.

WhatsApp)

WhatsApp)

Best in class is not an unachievable concept when it comes to horizontal grinding mill performance the most critical asset of a hard rock mining operation.

Outotec#174; Grinding Mills. Optimize grinding mill performance, efficiency, and availability to ensure you meet your plant''s operational targets. Outotec highperformance grinding mills use advanced simulation tools for the best possible process efficiency, mechanical reliability, and maintainability.

#0183;#32;Performance of grinding circuits has been improved in recent years by the development of machinery such as highpressure grinding rolls (HPGR) (roller presses), Horomills, highefficiency classifiers and vertical roller mills (VRM) for clinker grinding which are more energy efficient than machinery which has been in common use for many years such as tube mills.

#0183;#32;Best in class is not an unachievable concept when it comes to horizontal grinding mill performance the most critical asset of a hard rock mining operation.

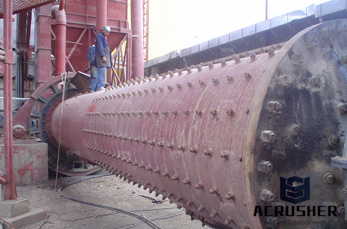

Improving operational performance with mill lining design. February 23, 2017 Features Ben Creagh. the lining of a grinding mill plays a key role in optimum comminution and mineral dressing.

#0183;#32;Improving operational performance with mill lining design. February 23, 2017 Features Ben Creagh. the lining of a grinding mill plays a key role in

The performance of tumbling mills is sensitive to the volumetric mill filling which influences grinding media wear rates, throughput, power draw, and product grind size from the circuit. Each of these performance parameters peaks at different filling values. In order to continuously optimize mill operation, it is vital to

#0183;#32;Analysis of a large amount of batch ball mill grinding data available in the literature has shown that the values of the power specific absolute rate of grinding of the topmost size fraction, S *, and the power specific absolute rate of production of 100 mesh fines, F *, are not independent of the mill operating conditions and mill diameter.

IsaMill Operating Principles. The IsaMill is a stirredmedium grinding mill, in which the grinding medium and the ore being ground are stirred rather than being subjected to the tumbling action of older highthroughput mills (such as ball mills and rod mills).

RESPONSE OF PRIMARY GRINDING MILL PERFORMANCE TO CHANGES IN OPERATING CONDITIONS USING AN ONLINE SURFACE VIBRATION MONITOR . K J Davey. 1, S J Spencer. 2, P L Phillips. 3, D G Barker. 4. and R J Holmes. 5, * ABSTRACT . Opportunities to monitor and control primary grinding mill performance are strongly sought after in the mineral processing

#0183;#32;In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters. The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance model.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement grinding.

grinding mill operating performancesharodin. Effects of slurry rheology on industrial grinding performance. Mill performance in terms of the Grinding Index, together with four operating variablesmill throughput (new feed recirculation), slurry density, slurry rheology and fines content in mill feedwere collected from the 45 industrial

Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding. The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding circuits.

#0183;#32;Optimization of Cement Grinding Operation in Ball Mills. Contact Us #187; . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

Mills usually operate in the range 65 82% of critical but values as high as 90% are sometimes used. A crucial parameter that defines the performance of a mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill

WhatsApp)

WhatsApp)