IBM uses big data to prevent mining equipment failures

#0183;#32;But it does operate the equipment that is used in mining, such as extractors and trucks. Thiess has more than 700 mining trucks and a bunch of extractors in

WhatsApp)

WhatsApp)

#0183;#32;But it does operate the equipment that is used in mining, such as extractors and trucks. Thiess has more than 700 mining trucks and a bunch of extractors in

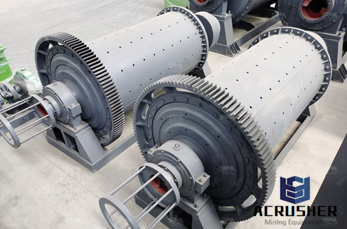

The mining industry has great needs for our products. This industry includes coal, gold, iron, and many other types of mines. The various machines and tools they use in open pits and underground mining require maximum attention and reliability. It is important that their equipment always stays operational as any delay or stoppage of operation

Mining Safety health, tips, education, information and advice

Some of the magnetic separators that are used in the mining industry include: Suspended plate magnets : As indicated by their name, these separators are suspended above the conveyor belt system. Electromagnet separators are extremely powerful and are able to extract tramp metal from fast moving belts with deep burden depths.

In 2008, competition in the coal mining industry became more intense than ever, leading to a demand for better technology and new mines. History of Mining Technology. In the beginning, miners used primitive tools for digging. Mining shafts were dug out by hand or using stone tools, making the entire process very lengthy.

Mining Industry Engineering Insurance . Electro winning is used at some mine sites in order to produce pure appropriate aggregate limit of indemnity and a specific deductible are usually agreed in respect of this special exposure of underground machinery and equipment in mining industry.

An Overview of Industrial Equipment Used in Oil and Gas Industry Vol 1. Wildcat drilling is also known as exploratory drilling, the process of drilling for oil or natural gas. Drilling in the area where the unknown and unexplored area for oil and gas is called wildcat drilling. Latest equipment made oil and gas production easier.

Each segment requires the use of specific equipment, but there are several types of mining equipment that are used throughout the industry. This equipment includes excavators, draglines, drills, roof bolters, continuous miners, longwall miners, rock dusters, shuttle cars and scoops.

After identifying the different fall hazards in the mine, like an elevator or mining shaft, a personal fall arrest system should be put in place. Fall protection equipment includes an anchor, body support, and connectors. Hand amp; foot protections: Miners should wear durable steel

Mining Equipment. Complex surface mining equipment is required as support in major mineral extraction process: they are Draglines, Shovels, Loaders, and Haul Trucks, the Mass Excavator. A Dragline Excavator. A Dragline Excavator is a large machine used to unearth dirt and other materials from construction sites and mining areas.

In order to speed up projects and make operations run smoother, movers are used alongside bulldozers and other heavy equipment which can do a similar job. This is easily one of the most important pieces of equipment for any mining job, and these units require specialist individuals to operate them.

Mining Equipment : Mining Equipment: Clean Coal: Coal To Liquid Fuels: Reclamation: Safety Related Equipment: End Uses of Coal: Mining Related Equipment . Equipment used in the Mining Industry today. Surveying; Complex Underground Equipment. Complex underground machines used directly or as support in the mineral extraction process:

Modern Mining Equipment Coal Education

Wheeltractor scrapers are used in the mining industry to dig into the surface of the ground and transport it to different locations using only one machine. This heavy equipment resembles a grader machine, except it has a hopper piece that is filled with the soil or clay materials.

Specialised underground mining equipment such as diggers, loaders, and trucks are used to excavate raw materials and transferred to the surface with lifts for future processing. In order to place...

CAE Mining and the Commonwealth Scientific and Industrial Research Organisation (CSIRO) have pushed the technology further by incorporating 3D imaging technologies in a Camera that can be used in open pit and underground mining areas to capture threedimensional images of the environment and topography, eliminating the need for geologists, engineers and surveyors to physically visit the mine.

The mining industry has developed a comprehensive view of the need to have production personnel well trained in the use and maintenance of mining equipment. A strong commitment from the industry

#0183;#32;Construction and mining equipment cover a variety of machinery such as hydraulic excavators, wheel loaders, backhoe loaders, etc. They perform a variety of functions like preparation of the ground, excavation, haulage of material, dumping/laying in a specified manner, material handling, road construction, etc.

Miners use augmented reality to train using virtual simulators, which also helps the industry reduce equipment maintenance costs. By using new technology like spatial data effectively, the mining industry gains insights into mine systems at a reduced cost and impact on the environment.

#0183;#32;Crushing equipment works in tandem with other mining equipment to achieve an end product to use for winterization road construction, and other similar projects. Screening equipment Screening equipment are machines that are designed to sort out raw materials by filtering the usable material from the waste material.

WhatsApp)

WhatsApp)