How Temperature Affect Grinding Efficiency

Pulverizer Wikipedia

WhatsApp)

WhatsApp)

Pulverizer Wikipedia

B. Miller, in UltraSupercritical Coal Power Plants, 2013. Grindability. Pulverizer systems, which integrate drying, grinding, classification, and transport of the ground fuel to the burners, can present the greatest problems when switching coals/fuels (Carpenter, 1998).Low quality fuels may have grinding properties that are markedly different from the pulverizer design coal (Kitto and Stultz

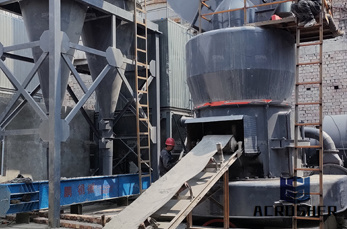

ATOX coal mill. Working principles The raw coal enters the mill via a rotary sluice and feed chute and is discharged onto the rotating grinding table. The rotation of the table accelerates the flow of material towards the grinding track, where the coal is ground between the table and the three rollers. The coal then continues over the dam

#0183;#32;Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some of its design...

Temperature Grinding Mill. Temperature Grinding Mill mbokodoinnscoza. Sales Inquiry Temperature Grinding Mill effect of temperature during cement grinding While grinding clinker with gypsum, time taken by the ball mill in while other factors like chemical composition, amount of gypsum, temperature etc. Get Price Online Chat. Read More

Inertization of coal mill circuit and fine coal bins with CO2, N2 or CO2+N2 to replace O2 which promotes spontaneous ignition of fine coal. Vertical roller mills can typically handle an aggregate moisture of up to 20% in raw materials and consumes about 30% less power in grinding.

Mill Inlet Temperature (0 C). Mill Outlet, bag filter outlet Temperature (0 C). O2 + CO Percent at bag filter outlet and in fine coal bins. Bag filter hopper and fine coal bin temperature (0 C). Elements of Coal Grinding System: Mill Feeding: Consists of following activities Coal Crusher: Generally, require when ball mill is used for grinding

Coal grinding temperature, Crusher solution. coal grinding temperature grinding mill temperature effect Coal Surface Mininggrinding mill temperature effect Description Cement mill Wikip

Temperature Grinding Mill. Temperature Grinding Mill mbokodoinnscoza. Sales Inquiry Temperature Grinding Mill effect of temperature during cement grinding While grinding clinker with gypsum, time taken by the ball mill in while other factors like chemical composition, amount of gypsum, temperature etc. Get Price Online Chat. Read More

Ball mills use in all industries needs a material grinding. Steel grinding balls use as grinding media in such mills. In this article, we will consider the steel grinding balls use in coal grinding. Coal grinding is preparatory process to a creating mixture for combustion in boilers at thermal power plants.

considers coal preparation in gasification plants. Know More. the bag filter, including the grinding mills, all the necessary The development of Loesche coal mills began with tworoller mills and table can be realised. This concept diameter grinding table. problems in such large, pressure resistant...

grinding mill for high temperature applications. grinding mill for high temperature applications. studies are illustrated with temperature analysis Welldesigned grinding processes usually enhance workpiece surface quality producing low roughness compressive or neutral residual stresses and improved fatigue life Grinding is a very efficient process for machining hard materials and has the

Coal Mill_Coal Grinding Mill_Coal Grinding Machine Coal dust is a type of fine coal powder ground by coal grinding mill size range and most of powder s size range 20 50m. Pulverized coal processed by grinding machine could be fully burned use ratio very high and we have provided technical support for many power plant.

Temperature Coal Mill Grinding; Temperature Coal Mill Grinding. Our company has been devoted to mining machinery for 40 years. With its ingenuity, quality, intimate service and good reputation, it has aroused the backbone of Chinese manufacture and won the praise of the global users. We also choose us as a successful enterprise and a bright

grinding by means of ball mills, which are being applied at heat power stations for grinding the coal, at cement plants for grinding the clinker and at ceramic plants for grinding the clay. The developed system provides continuous monitoring of the grinding, ventilating and drying productivities and it optimizes

Coal mill atex zoning example a compact coal mill solution for any type of raw coal our atox is a compact vertical roller mill that almost any type of raw coalhe utilises compression and shear force generated between the and the rotating table to crush and grind removing the need for a separate. read more.

Grinding mill design ball mill manufacturergrinding mill design ball mill manufacturerTable of contentstypes of grinding mill manufacturedrod millspebble millsselecting wet or dry grinding millhow much grinding power is neededsag mill vs ball millmill, grinding mills ball mill temperature display

Coal dust is a type of fine coal powder ground by coal grinding mill, size range ~, and most of powders size range 20~50m. Pulverized coal processed by grinding machine could be fully burned, use ratio very high, and we have provided technical support for many power plant.

WhatsApp)

WhatsApp)