Ball Mill Design Parameters Of Vibrating Screen | Crusher

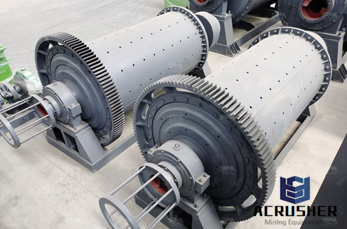

Design Parameters For A Ball Mill Ball Mill Design/Mineral Ball Mill/Grate Ball Mill/Overflow The grate ball mill is roughly composed of the cylinder, cylinder liner,big gear ring,

WhatsApp)

WhatsApp)

Design Parameters For A Ball Mill Ball Mill Design/Mineral Ball Mill/Grate Ball Mill/Overflow The grate ball mill is roughly composed of the cylinder, cylinder liner,big gear ring,

Design parameters of ball mill design parameters of ball mill the ball mill is a tumbling mill that uses steel balls as the grinding media the length of the cylindrical shell is usually 115 times the shell diameter figure 811the feed can be dry with less than 3 moisture to minimize ball coating or slurry containing 2040 water by weight .get price

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

Ball mill design,The technology to design high performance Design and operational parameters of the ball mills sampled. Circular Vibrating Screen; In order to design a ball mill and to calculate the specific energy

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

#0183;#32;The aim of this work was to optimize the ball mill based refining process of chocolate, in terms of refining time and energy consumption. Experiments were planned following a central composite design (CCD), considering refining time (rt) and agitator shaft speed (as) as experimental variables measured were chosen from the main characteristics that describe unmoulded chocolate.

With a view to developing a sound basis for the design and scaleup of ball mills, a large amount of data available in the literature were analyzed for variation of the two key mill performance

Ball mill design is rather simple. This grinding equipment is a drum filled with metal or cast iron balls ( grinding media ). It is used mostly for production of bulk construction materials, paints, pyrotechnical devices, ceramics and in other industries.

design parameters for a ball grinding mill. Aug, calculation of ball mill capacity the production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting there are many factors affecting the production capacity of the ball mill, in addition to the nature of the material grain size, hardness

#0183;#32;The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific

design parameters for a ball mill in haiti. How To Design Parameters For A Ball MillBall Mill. Design parameters of ball mill design parameters of ball mill the ball mill is a tumbling mill that uses steel balls as the grinding media the length of the cylindrical shell is usually 115 times the shell diameter figure 811the feed can be dry with less than 3 moisture to minimize ball coating or

design parameters for a ball grinding mill. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size,

operating parameters other than ball level, such as pulp density and liner configuration. Figure 2 shows that there is no linear relation between mill absorbed power and ball filling degree. As indicated on the graph, a small variation in power could be the result of a significant variation of balls filling degree.

WhatsApp)

WhatsApp)