(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL

mentioned that a hammer mill with 16 hammers, a mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of mm

WhatsApp)

WhatsApp)

mentioned that a hammer mill with 16 hammers, a mm screen, and an operating speed of 3600 r pm was more effective at grinding a mixture of mm

A hammer mill is typically good for grinding softer materials with Mohs hardness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10. High hardness materials become very abrasive; therefore, they are not suitable for highspeed hammer mills. In a typical jet mill, grinding

Design books grinding hammer mill hammer mill. Design books grinding hammer mill hammer mill. Hammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers usually four or more hinged on a central shaft and enclosed within a

#0183;#32;High production hammer mill. Reduces a variety of wood materials to desired size. The 44 inch rotor diameter of the 15 Series Wood Grinder provides the tip speed required for maximum throughput using an 1800 rpm motor.

design books grinding hammer mill hammer mill in madagascar. Jul 19 2018 #183; The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a . Leave Message Get a Quote. Hammer Crusher.

HAMMER MILLS 2 Sammons Court Bolingbrook, IL 60440 Tel: Full Screen design, a proven system that ensures use of the entire available majority of grinding takes place, increasing throughput capacity without increasing power requirements. The design improves access to working parts simplifying screen changes.

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little machines have numerous industrial applications, including: Ethanol plants (grains); A farm machine, which mills grain into coarse flour to be fed to livestock; Fluff pulp defiberizing; Fruit juice production

File: design books grinding hammer mill Latest Release: GMT By: Beautiful ISBN10 Format: pdf grumpy''s books, frankfurt book fair gypsy romani, christian clipart year c book cd, to kill a mockingbird book, christmas symbols coloring book, moodle books, quilt books, recent book endorsements from opr, definition of picture books genre, book extracts, it can''t happen here

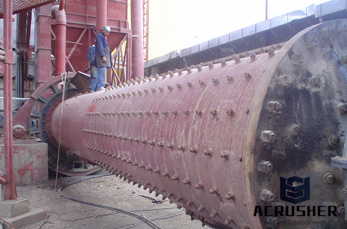

Hammer mill is a new generation of our company''s research and development for the production of 03MM coarse powder. The machine followed the crushing machine principle of work, makes up the shortage of traditional milling machine product particle size range, become the core equipment of the production of coarse particles.

We supply a wide range of Hammer Mills. These high quality mills can be used to grind almost any dry or wet substance/product to personal specification. Please look through our product list, and contact us with your order. Contact Phone Andre: 072 306 1136

a hammer mill, producing maize flour of acceptable quality. These mills are in widespread use in rural parts of the world in areas where no electricity grid is available. Dieselpowered grain mills are limited to areas with access to fuel and spare parts. Plate 1 Traditional rubbing and hand grinding stones F A O /

The detailed design procedure for a hammer mill machine is presented. The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screen.

hammers (generally rectangular pieces of hardened steel) which are attached to a . shaft. that rotates at high speed inside the mills . grinding chamber. The material is crushed or shattered by a combination of repeated hammer impacts, collisions with the walls of the grinding chamber, and particle on particle impacts. Perforated

Hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact. Material is fed into the mills chamber through the feed chute, typically by gravity, where it is struck by ganged hammers attached to a shaft that rotates at high speed inside the mills grinding chamber.

Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed ingredient [5].

The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources . The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile. Further more, the hammer was redesign to twisted type as

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

WhatsApp)

WhatsApp)