There''s Gold in Them Thar Plants | Phytomining | Live Science

Processing the ash poses difficulties, too, and requires the use of huge amounts of strong acids, which can be dangerous to transport. The gold found in plants are nanoparticles,

WhatsApp)

WhatsApp)

Processing the ash poses difficulties, too, and requires the use of huge amounts of strong acids, which can be dangerous to transport. The gold found in plants are nanoparticles,

Demonstrating a golden opportunity in environmentallyfriendly processing. A low cost demonstration plant for technology that can overcome the environmental risks and regulatory barriers associated with the use of cyanide in gold recovery, could hold the key to unlocking stranded Australian deposits.

Taking the gold cyanidation plant with processing capacity of 100000 tons and gold grade of g/t as an example, gold CIL process can save the investment cost of 486000 than the CIP process, reduce the capital backlog of 201700, save and recycle capital of 675100 in advance excluding the cost of activated carbon. 2.

Sabodala Gold Project (SARL), Senegal Engineering, Procurement, Construction Management, Commissioning and Performance testing services for the delivery of the Mt/y gold mine processing plant and associated infrastructure, including a 650 person accommodation facility, mine vehicle workshops and light industrial areas.

Nelson Machinery sells mining amp; mineral processing plants to recover amp; process gold, silver, and precious metals. Equip yourself with the gold standard.

The gold grade in the ore is /t, mainly fine particles, and little microparticles. Most of which are concentrated in the range of Natural gold is mainly embedded in pyrite, mainly inclusion gold (%), followed by cracked gold (%). Mine PreDevelopment Site Inspection for a Gold Mine. 2. Processing Plant

#0183;#32;Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Gold Carbon In Leach Plant Updated January, 2017. Gold Carbon In Leach Plants Updated January 2017. Gold Processing Plant, Carbon In Leach (CIL) Plant. A Carbon In Leach Gold Recovery Plant. This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is

#0183;#32;Fourth reasons why you should check out our new Mobile Gold CIL Plant: flexibility, versatility, reliability, and security. https:

We offer and recommend our gold recovery training at our USA facility, for no additional cost, when purchasing our gold mining equipment. Large Scale Proven From the Yukon through the Rocky Mountains and into the Jungles, we have designed and manufactured equipment plants / systems processing 1,500+ tons of ore per hour.

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore

Vibratory gold wash plants work well in clean sand and gravel materials. They are not recommended for clay or sticky materials. The sizing of sluices, when using a vibratory wash plant, is extremely important to maintain proper gold recovery.

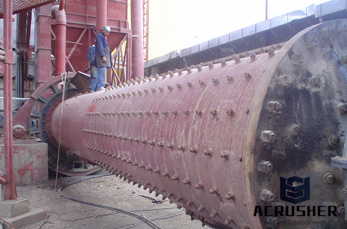

6,000 10,000 TPD CRUSHING/GRINDING CIRCUIT GOLD PLANT with 32'' x 12'' SAG Mill, '' x 28'' Ball Mills, 54quot; x 74quot; Gyratory, 7'' SH HD Cone, Rock Breaker and More. Inventory ID: 18CVI01 Manufacturer: ALLIS CHALMERS

Taking the gold cyanidation plant with processing capacity of 100000 tons and gold grade of g/t as an example, gold CIL process can save the investment cost of 486000 than the CIP process, reduce the capital backlog of 201700, save and recycle capital of 675100 in advance excluding the cost of activated carbon. 2.

At current gold prices this is worth about US600. Both smelter treatment charges and oxidation or bioleach costs are at least 200/t of concentrate and payables/recovery in the 90% range, so a minimum GSR for effective downstream processing is around

#0183;#32;Fourth reasons why you should check out our new Mobile Gold CIL Plant: flexibility, versatility, reliability, and security. https:

Processing the ash poses difficulties, too, and requires the use of huge amounts of strong acids, which can be dangerous to transport. The gold found in plants are nanoparticles,

One Man Gold Wash Plant Installation. The IRG 100 Gold Processing Plant arrives on 4 pallets: i150 Concentrator and VFD; iPump with VFD; iScreen 12 Inch x 24 Inch with VFD; Installation Kit; Package details: 1 crate 204 kg 64 x 76 x 145 cm. 1 crate 155 kg

The gold prices used in this table and chart are supplied by FastMarkets. Where the gold price is presented in currencies other than the US dollar, it is converted into the local currency unit using the foreign exchange rate at the time Processing, smelting and refining gold.

WhatsApp)

WhatsApp)