24K pure GOLD: the refining process PART 1 YouTube

#0183;#32;Refining 193g Au, recovered in the previous videos, to 24K

WhatsApp)

WhatsApp)

#0183;#32;Refining 193g Au, recovered in the previous videos, to 24K

In the process slag is poured off the top of the melt into a crucible and allowed to slowly cool so any gold that has been caught up with the chlorides will settle to the bottom where it can be recovered as a button of gold when the crucible has cooled completely; it is then added to the remaining molten gold. In this process the particles of gold remaining in the crucible are carefully removed by hand as well as the

Describes the Miller Chlorination Process used in gold refining in all its steps and chemistry. The reactor and chemical used to obtain pure % gold bars.

Millers Gold Chlorination process was introduced by Miller. The refining process employs chlorine gas, which passed into molten gold covered with a layer of borax and silica, and reacts with most of metals present in the molten charge. Platinum group metals do not react. Basically, gold is slightly attacked in the first moments and all the chlorides formed rise to the surface and are

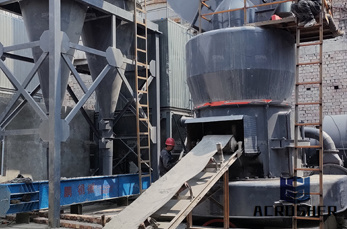

miller process gold refining machinery. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals.

In gold processing: Refining commonly employed for purification: the Miller process and the Wohlwill process. The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily than gold does at temperatures equal

There are two main methods of refining goldthe Wohlwill process or the Miller process. The Wohlwill process was invented in 1875 by Emil Wohlwill and produces gold to a high degree of purity ( percent). The Wohlwill process is an electrochemical process. The Miller process produces a slightly lower purity of gold, only percent pure.

authority on gold metallurgy, and the chlorine refining process was chosen specifically with a view to the rapid and effective treatment of large amounts of bullion. This process had been patented by Miller, Assayer of the Sydney Mint, in 1867 and used in Australia since 1872 in contrast to the Lon#173;

#0183;#32;I''m doing a research on gold refinning processes available in market. I have not found any figure, drawing, schem or flowchart of the miller chlorination process. As I know there is a lot of people who understand a lot about gold refinning here, is tere anyone who could send me a picture, a schem, a draw, anything? Thanks a lot..

miller process of crushering gold. Millers process of refining impure gold with chlorine gas patented in Britain in 1867 and Emil Wohlwills electrorefining process introduced in Hamburg Ger in 1878 it became possible routinely to achieve higher purities than had been allowed by fire refining...We are a professional mining machinery manufacturer, the main equipment including: jaw crusher

From Wikipedia, the free encyclopedia The Miller process is an industrialscale chemical procedure used to refine gold to a high degree of purity (%). It was invented by Francis Bowyer Miller (patented 1867). This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, gold.

The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily than gold does at temperatures equal to or greater than the melting point of gold. The impure gold is therefore melted and gaseous chlorine is blown into the resulting liquid. The impurities form chloride compounds that separate into a layer on the surface of the molten gold.

When I use this refining method, I regard the purity of the gold as 22kt, and I alloy it accordingly down to 18kt or 14kt. This gives me a safety margin so the gold is a slightly higher purity than I stamp it. Safety disclaimers notwithstanding, this process uses nitric acid at

gold refining miller process . Homegt;gt;Case Linegt;gold refining miller The Miller Chlorination Process and Wohlwill in hydrometallurgical processes for gold recovery miller process of refining gold from ore impurities of gold refining such as the wohlwill from ore various refining processes are then popular process

#173;The final stage of gold production refining involves removing impurities that remain after the smelting companies receive dor#233; bars, as well as scrap gold, and reliquefy the metal in a furnace. Workers add borax and soda ash to the molten metal, which separates the pure gold from other precious and less precious metals. A sample is then taken to a lab for tests, or

#0183;#32;Electrolytic Refining Process of Gold . Q. Dear Sir, I would like to know how to recover Gold from Silver Sludge which comes out from the Wohlwill Cells (Electrolysis). We are actually washing it by ammonia. And today through your site I came to know that it is dangerous. Please let me know that how can you recover Gold from that Silver Sludge.

#0183;#32;Gold Refining process flow explained in details

WhatsApp)

WhatsApp)