One stop solution for Cement plant Spare partsSpare

Pengfei Group is the global export base of industrial kiln and energysaving grinding equipment, the industry One Belt and One Road strategy and the International Capacity

WhatsApp)

WhatsApp)

Pengfei Group is the global export base of industrial kiln and energysaving grinding equipment, the industry One Belt and One Road strategy and the International Capacity

cement plant spare parts best cement plant spare parts. Buy quality cement plant spare parts products from Agent (111 ) Importer (59) we produce EQUIPMENT AND SPARE PARTS FOR THE CEMENT PLANTS equipment and spare

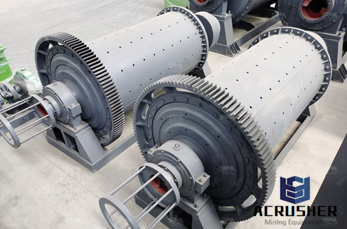

As a cement equipment supplier and cement plant manufacturer, AGICO offers quality cement kiln, cement vertical mill. cement ball mill, hammer crusher, etc. Besides, we provide cement production line, stone crushing plant, etc.

Our expertise and knowledge of the cement sector means we have a good understanding of materials and can provide advice on material suitability in terms of robustness and suitability to do the job. We understand the environment that the machinery will operate in and can fabricate products robust enough to be used for specific applications within the cement industry.

Within the cement industry, we supply spare parts for ball mill, cement kiln, calcining equipment, clinker coolers and any equipment necessary for a cement plant. We are primarily focused on minimising the downtime along with increasing the efficiency of the manufacturing unit.

Spare parts for cement industry. We are committed to provide every spare part or service that cement plants need to operate. We have partnered with European manufacturers and are already supplying original spares and parts to several cement plants in World.

Sara Engineering Wholesaler of Heavy Machinery Engine Parts, Cement Plant amp; Ambuja Cement Plants from Chandrapur, Marashtra, India

Within the cement industry, we supply spare parts for ball mill, cement kiln, calcining equipment, clinker coolers and any equipment necessary for a cement plant. We are primarily focused on minimising the downtime along with increasing the efficiency of the manufacturing unit.

Matcon Industries has also Involved in manufacturing certain Equipments for Cement Manufacturing Industries like Grinding Mill, Raw Mill, Contineous type Ball Mill, Kiln, Cooler, Screw Conveyor, Bucket Elevater, Bearing Housing, Hoppers, Rotary Feeder, Table Feeder, Diverting Valves, Flap Valve, Vibratory Feeders etc..

Cement Plant Machinery is a key and major machine, equipment to set up a cement production line. Cement plant machinery covers rotary kilns, ball mills, vertical roller mills, hydraulic roller press and crushers. Cement production can be mainly divided into five steps: raw material production, raw material grinding, clinker calcining, cement

UK agent for Larox Flowsys. Larox manufacture abrasion resistant Automatic and Maual Pinch Valves a Hasmak is a general contractor company specialized in cement plant constructions, steel fabrication, Heavy Mechanical Complex (Pvt) We are the manufacturer of all kind of machinery maintenance parts. We are registeresd with all well

Find details of companies offering cement plant parts at best price. Listed manufacturers, suppliers, dealers amp; exporters are offering best deals for cement plant parts.

We have a huge range of parts in stock available for next day delivery! Spares amp; consumables for light and heavy plant machinery as well as engine spares and garden machinery. Genuine and aftermarket parts available for Stihl, Belle, Husqvarna, , , Honda and more.

Hydraulic Plant Services Ltd only offer quality plant spares that you can rely on. We can supply genuine mini digger parts, dumper spares, roller parts, mixer spares and large excavator parts, plus virtually any other spares part for plant machinery. Established in 1978, Weve been selling plant parts for 40 years.

agent for cement plant machinery and parts,Agent For Cement Plant Machinery And Parts We provide you with all accessories of mining machinery and equipment produced by our company with complete models reliable performance stability and durability Ensure the first time to meet customer parts replacement needs reduce customer downtime maintenance time

After cooling, the clinker may be stored temporarily in a clinker store, or it may pass directly to the cement mill. The cement mill grinds the clinker to a fine powder. A small amount of gypsum a form of calcium sulfate is normally ground up with the clinker. The gypsum controls the setting properties of the cement when water is added.

WhatsApp)

WhatsApp)