Manganese the third electric vehicle metal

Mar 24, 2017#0183;#32;At Mato Grosso, there are two types of manganese mineralization cobbles/clasts and hydrothermal veins. Maxtech will need to calibrate its exploration

WhatsApp)

WhatsApp)

Mar 24, 2017#0183;#32;At Mato Grosso, there are two types of manganese mineralization cobbles/clasts and hydrothermal veins. Maxtech will need to calibrate its exploration

Manganese Mining and Processing: Everything you Need . Where Does Manganese Mining Occur? Manganese is the fifth most abundant metal found in the crust of the earth. Although 80 percent of manganese resources are found in South Africa, manganese is also mined in Australia, China, India, Ukraine, Brazil and Gabon.

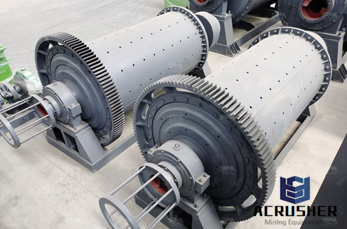

mining manganese ore process in colombia. The manganese ore flotation machine is mainly used for the flotation of manganese carbonate ore and polymetallic manganese ore and is suitable for ore sorting of finegrained inlays There are many types of manganese ore mining process methods and manganese ore beneficiation equipment...We are a professional mining machinery manufacturer, the

Manganese. Manganese (element #25, symbol Mn) is a graywhite metal with a pinkish tinge, and is very brittle, but hard. It was discovered 1774 by Johann Gn. Manganese easily reacts with water and air. On Earth, manganese is never found as a free metal, but it is found in a number of minerals.

This changes the properties and essentially makes the metal customizable. This is an extremely common type of metal because its generally still very cheap to make. Common alloying elements for steel include manganese, vanadium, chromium, nickel, and tungsten. Each of these elements will modify the metals properties in different ways.

Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron orebased steel made it even harder. In todays world, manganese is often used for cathodic shielding in the battery industry. The Basics of

Manganese is a chemical element with the symbol Mn. It is a silvery white metal with a hard brittle structure that belongs to the group 7. Manganese are the fifth most abundant metal found in the crust of the earth that are distributed widely in many countries.

Nov 19, 2020#0183;#32;Manganese is a transition metal with a multifaceted array of industrial alloy uses, particularly in stainless steels. Manganese sits near vanadium, chromium, iron and cobalt on the periodic table...

That metal is manganese (Mn), a chemical element that is normally found together with iron. Since the beginning of 2016, cobalts price has jumped 120%, lithium has moved up 77%, and manganese

Manganese mining often requires a specific method of extraction, because nodules can be embedded among various other rock bed materials. One of the benefits to openpit mining is reduced cost compared to other mining methods. The change in geologic configuration, however, means the environmental impact of this mining is often considered severe.

Mining is the extraction (removal) of minerals and metals from earth. Manganese, tantalum, cassiterite, copper, tin, nickel, bauxite (aluminum ore), iron ore, gold, There are two types of small scale mining: land dredging and river dredging:. Read more

On Earth, manganese is never found as a free metal, but it is found in a number of minerals. The most important of these minerals is pyrolusite, the main ore mineral for manganese. Manganese is essential to iron and steel production. The, Japan, and Western Europe are all nearly deficient in economically mineable manganese.

Manganese is a chemical element with the symbol Mn. It is a silvery white metal with a hard brittle structure that belongs to the group 7. Manganese are the fifth most abundant metal found in the crust of the earth that are distributed widely in many countries.

Medium grade manganese ore (35%44% Mn) Low grade manganese ore (25%35% Mn) Classification according to chemical constituents; Manganese is found in more than 100 minerals including various sulphides, oxides, carbonates, silicates, phosphates and borates. The most commonly occurring manganesebearing minerals:

Wear Plate Casting, Wear Resistant Casting, High Manganese Steel manufacturer / supplier in China, offering Sand Casting High Manganese Steel Wear Resistant Casting for Steel Industry/Mining Machinery/Agriculture Machinery, Aluminium Alloy Gravity Die Casting Metal Parts for Auto Parts/Pump Parts/Valve Parts, OEM High Pressure Aluminum Alloy Die Casting Components for Auto Parts and

The most important manganese ores are the oxides pyrolusite, romanechite, manganite, and hausmannite and the carbonate ore rhodochrosite. Rhodonite and braunite, both silicate ores, are frequently found with the oxides. Only ores containing greater than 35 percent manganese are considered commercially exploitable.

2 #0183;#32;Manganese processing Manganese processing The metal and its alloys: More than 90 percent of the manganese produced goes into metallurgical applications, the pure metal being used in copper and aluminum alloys and ferromanganese and silicomanganese employed in steel and cast iron. Most manganese is consumed as highcarbon ferromanganese for addition to carbon steels.

WhatsApp)

WhatsApp)