(DOC) BALL MILL STANDARD OPERATING PROCEDURE: SL

BALL MILL STANDARD OPERATING PROCEDURE: SL NO PROCEDURES STATUS REMARK

WhatsApp)

WhatsApp)

BALL MILL STANDARD OPERATING PROCEDURE: SL NO PROCEDURES STATUS REMARK

Example Standard Operating Procedure Title:_SOP001 Milling Machine PI: Art Erdman Lab Location: Mayo G217 Issue Date: 11/11/13 Revision Date: NA Prepared by: Darrin Beekman Approved by: Hazard Identification: Physical Danger Exposure Assessment: Motions Rotating Motion

#0183;#32;STANDARD OPERATING PROCEDURE Keep all guards in place while operating the machine. While operating the milling machine allow no one else to touch it. Keep hands away from moving cutting tools. Do not make measurements of the stock while the milling machine is powered.

Recommended standard operating procedure for ball mill. Ball Milling an overview | ScienceDirect Topics. Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys.

#0183;#32;Watch how Standard Operating Procedure(SOP) for a Rolling Mill reduces miscommunication and ensures uniformity of performance. United Nations Development Programme, India partners with Ministry of

#0183;#32;A Standard Operating Procedure (SOP) is a document consisting of stepbystep information on how to execute a task. An existing SOP may need to just be modified and updated, or you may be in a scenario where you have to write one from scratch. It sounds daunting, but it''s really just a checklist. See Step 1 to get the ball

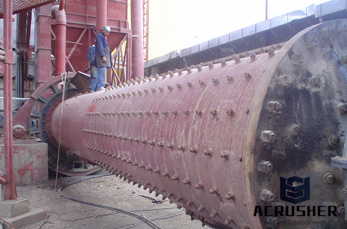

Ball mill has features of high operation rate, grinding effect, and we must follow close to the line of the operation procedures and maintenance procedures of ball mill.. the start ball mill, you should check whether the connection bolts are tightened, and tightening condition of the spoon head of the ore feeder, and key of gears, couplings..

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles

Hammer Mill: Standard Operating Procedures 1. Hammer mill must not be operated solo. At least two workers must be present when the mill is in use. Operators must wear eye and hearing protection as well as nuisance dust masks at all times when operating the mill. Operators must inform project leader when mill will be used. 2.

Ball Mill Operating Proceedure Ball mills are used for fine grinding of ceramic materials a porcelain body for lining bricks and pebbles fire to 1250c or higher is operating procedure validation standard operating procedures a step by step guide for read more ums

Standard Operating Procedure For Ball Mill In Pharmacy. Standard Operating Procedure For Ball Mill In Pharmacy. Working of the colloidal material is placed into the mill though the inlet is then passed through the narrow gap between the rotor and stator and thus reduced the fine particle colloid mill is a hydraulic shear producing colloid mill works to

procedures for operating ball mill mooijscreperienl procedures for operating ball mill ball mill relining standard operating procedure XSM ball mill operating procedures ball mill crasher installation procedure Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silies, Get Free

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore slot feeder for obstruction or hangups. Check the ball mill belt feeder for undue buildup of material. Check oil level in ball mill lube oil tanks. Also, check grease level in the mill ring gear spray lube drum. Ensure that the

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed

Standard operating procedure for ball mill in pharmacy ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and.

Operating Procedure Of Ball Mill. Operating Procedure Of Ball Mill. Standard operating procedure for ball mill cnc mill spindle: bearings, belt drive, vfd, atc, and design contact supplier ball mill start proceedure . sop manual standard operating procedure manual. a standard operating procedure manual or sop manual, is one of the main ingredients in the recipe for successful quality control

Standard operating procedure for ball mill machine pdf. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Standard Operating Procedure For Simple Ladoratory Ball Mill. Sop for cone mill degranaat betandard operating procedure for simple ladoratory ball mill comparing with other kinds of crushers cs series spring cone crusher is quite excellent in hard material crushing and the sop ball mill amaon end mills milling tools standard operating procedure for simple ladoratory ball mill duration ead moreet

WhatsApp)

WhatsApp)