Ball mill animation YouTube

#0183;#32;In the ball mill, both the shearing and impact forces are utilized in the size reduction.

WhatsApp)

WhatsApp)

#0183;#32;In the ball mill, both the shearing and impact forces are utilized in the size reduction.

Calcium carbonate (CaCO 3), which occurs primarily in the form of the minerals calcite and aragonite, is one of the most prevalent compounds on carbonate is not only the main component of marble, limestone and dolomite, it is also found in bones and teeth as well as the exoskeleton of crustaceans, coral, muscles, snails and protozoa.

Sepors 16 x 32 continuous ball or rod mill is ideal for pilot plant studies of ore grinding and processing or just regular small scale grinding requirements you may have. The mill can be used in a closed circuit, with a spiral classifier, screen or cyclones or as a single pass grinding mill.

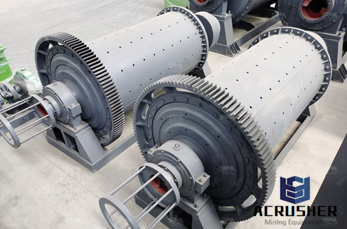

Ball mill liners may be made of hard cast iron when balls of up to 5 cm in diameter are used, but otherwise cast manganese steel, cast chromium steel, or Nihard are used. Ball Mill liners are a major cost in mill operation, and efforts to prolong liner life are constantly being made.

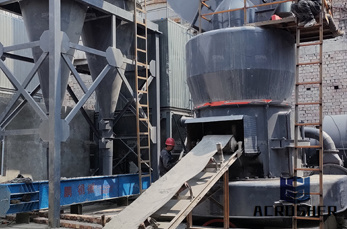

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc. Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill.

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle, which greatly reduces the

We sent a substantial amount of quartz gold ore to a mill for processing. After a couple hundred tests on the material an average grade was calculated. After milling for several days the mill says there is way less gold in the ore than what had been estimated. Once milling began samples were take

#0183;#32;A ball mill mineral can be used to grind both wet and dry products and there are two types of ball mills namely over fall type and grate type depending on the different ways they discharge materials. There are also many types of grinding media and there properties are density, size, composition and hardness.

How is the ball mill applied to mineral grinding composed? XInihai Ball mill is widely used in the mining industry and other manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, it also can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

PulpMax mill liners are highperformance, lightweight mill liners that are constructed with a rubberceramic matrix and reinforced with carefully selected highhardness steel inserts. FL stated that the composite design incorporated in its new PulpMax mill liners ensures that users get reduced downtime and maintenance, increased throughput and improved worker safety.

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Effective Planetary Ball Mills. The planetary ball mill will rapidly grinding the samples to be less than than the traditional function of mixing and grinding, our Planetary Ball Mill also widely applied for the scientific research job with high precision requirement, also gridning the different kinds of specimens such as soft, hard, brittle, suspension in the lab.

Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken. The mass moves up the wall of the cylinder as it rotates and falls back into the toe of the mill when the force of gravity exceeds friction and centrifugal forces.

How is the ball mill applied to mineral grinding composed? XInihai Ball mill is widely used in the mining industry and other manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics, it also can be used for the dry and wet grinding for all kinds of ores and other grindable materials.

The equipment mainly comprises 420#215;450 Grate Ball Mill, 150#215;1200 Screw Classifier, 35 liter Swing Feeder and 90#215;600 Screw Conveyor and can conduct grinding operation continuously in a close comes with the factory fit electric devices and water supply requires no additional foundation.

The ball mill is an essential grinding equipment for concentrators. It is mainly used for grinding operations before sorting. It is equipped with grading equipment for grinding and grading to complete the sorting of minerals. It is widely u. Ingenuity makes success: 3711 5575.

WhatsApp)

WhatsApp)