Environmental impact of iron ore mining Wikipedia

Mining of Iron Ores |

WhatsApp)

WhatsApp)

Mining of Iron Ores |

Jun 22, 2018#0183;#32;However, the process of mining for ore is intricate and requires meticulous work procedures to be efficient and effective. This is why we have broken down the mining process into six comprehensive steps. Prospecting/Surveying. The first stage in the mining process calls for skilled workers or AI to apply their geological knowledge in identifying areas where a particular ore can be

Iron processing Iron processing The metal: Most blast furnaces are linked to a basic oxygen steel plant, for which the hot metal typically contains 4 to percent carbon, to percent silicon, percent sulfur, to percent manganese, and percent phosphorus.

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

Extraction processes include dressing (picking, sorting, washing of ores), milling (crushing, grinding, etc.) and beneficiation (processing to improve purity/quality). Wastewater is generated during the mining process from groundwater produced during ore extraction, from water used by operators for equipment cooling and dust control, and from precipitation entering mines.

The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and include magnetite, hematite, limonite, and many other rocks. The iron content of these ores ranges from 70% down to 20% or less.

Integrated mining and processing strategies reduce costs and maximize profit at iron ore operations. Author (s) W. Valery, K. Duffy, P. Holtham, A. Jankovic, S. Vianna, E. Tabosa, R. Hayashida. Brazilian Metallurgy, Materials and Mining Association (ABM) Week 2019 Conference in S#227;o Paulo, Brazil October 13, 2019.

Mar 14, 2014#0183;#32;The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state. It consists of several distinct steps. The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore body.

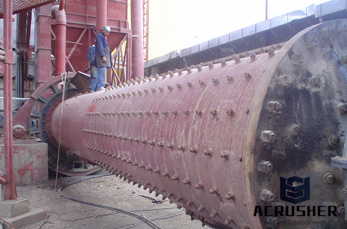

Jun 01, 2015#0183;#32;Mining, blasting, crushing, concentrating, agglomerating are some of the terms associated with mining process. Lets talk about them as well as machinery, and processes that arent the elements of everyday conversation to folks outside of the mining

MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines. Manual mining method is normally limited to float ores and small mines. Mining of reef ore is also being done manually on a small scale.

Oct 01, 2018#0183;#32;In this study, a lifecycle model for mining and processing of Chinese iron ores is developed and used to estimate GHG emissions. Results show that the mean lifecycle GHG emissions for Chinese iron ore production are 270 kg CO2e/tonne, with a 90% confidence interval ranging from 210 to 380 kg CO2e/tonne.

Iron ore processing. After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually processed. The aim of this is to reduce the undesirable high proportion of admixtures to a desired minimum in order to increase the iron content. This is done by processes such as flotation or magnetic separation. Subsequently, the milled ores are lumped by sintering or pelletizing in order to

The course is designed to explain what the users of iron ore are looking for in both physical and chemical properties and how processing the ore can create the necessary properties. Participants will look at the typical types of iron ore deposits and how each may be processed to achieve a sellable product.

WhatsApp)

WhatsApp)