EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS

Determination of milling parameters in each ball size interval Table selection function parameters in the different ball intervals used. Index Ball size interval (mm) a (min1) (mm) 1 2 3 4

WhatsApp)

WhatsApp)

Determination of milling parameters in each ball size interval Table selection function parameters in the different ball intervals used. Index Ball size interval (mm) a (min1) (mm) 1 2 3 4

Save now on high quality ball end mills with low prices. Carbide ball nose end mills are the highest performance. Ball nose sizes range from .005quot; to 1quot;. Available in stub, standard, long, and extra long, and extra extra long lengths.

Commercial ball sizes 10 150 mm; Number, size and mass of each ball size depends on mill load and whether or not the media is being added as the initial charge. For the initial chargin of a mill, Coghill and DeVaney (1937) defined the ball size as a function of the top size of the feed,, dV = KF

Break Down Of A Ball Mill Schematic. Break Down Of A Ball Mill Schematic Mineral ball mill process diagram_BALL MILL POWDER PROCESS YouTube Oct 22, 2016 Ball mill Wikipedia, the free encyclopediaA ball mill is a type of grinder us The grinding media may be the ore itself (autogenous grinding), bars, balls, or cylpebs, or even the Schematic representation of a tribosystem [6].

Table 1: Bond Ball Mill Grindability Test Summary Closing size, #181;m Copper Mountain F80 (#181;m) P80 (#181;m) Gram per Revolution Work Index (metric) Specific Energy, kWh/t 300 GeoMet Composite SAG Belt End SAG Belt Start SAG Belt Mid 212

End Mill Size Chart (pdf) The above link provides a printable and downloadable chart of the table below. This table shows end mill diameter sizes for inch, metric, and micro milling bits from quot; to 1quot;. All of these sizes can be searched by clicking the End Mills tab at the top of the page. Some inch sizes below are linked below to make it

Stampard Sizes For Ball Mill gloeipeelenmaas. icf for ball mill ecolelenvolee. The 8000D Mixer/Mill is a highenergy ball mill with dual clamps that grinds up to grams of dry brittle samples. It reduces samples to analytical fineness and can be utilized for mechanical . /5(41) Get P; ball mill sizes Mobile Crushers all over the World.

Economy Ball Mill 14654 HWY 57 Box 237 Tollesboro, KY 41189 (606) (606)

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

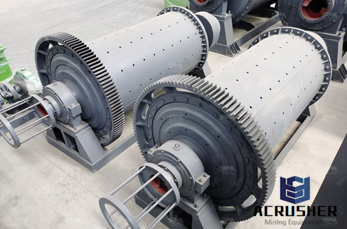

The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material (feeders), and the system for discharging the output product. The size of a mill is usually characterized by the ratio length to diameter and this ratio most frequently varies from to The

#183; The present work aims at exploring the size reduction of Al 2 O 3 using three mill types; single ball mill, air jet mill and planetary ball mill. In a similar manner to previous studies ( Zhou and Snyder, 1991, Knozinger and Ratnasamy, 1978 ), Xray diffraction (XRD) and Transmission Electron Microscopy (TEM) have been used to characterise the milled powders.

system breakdown structure ball mill. Work Breakdown Structure (Rev E June 2003) WORK BREAKDOWN STRUCTURE A project work breakdown structure (WBS) is a deliverable or product oriented grouping of project work elements shown in graph ical display to organize and subdivide the total work scope of a project The WBS is a particularly important project tool Sep 23 2015Advertisement

break down of ball mill sizes [ 8322 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products.

The mill (with 30 cm in diameter and 30 cm in length) and the test conditions are standardized, with a maximum ball size of 40 mm and an ore top size of mm. With less than 300 balls, it poses no challenge in running the simulations, if only grinding media are included. For such a small mill, one could also include the ore or powder charge.

Ball size depends on initial size of charge and ranges from 10mm150mm dia. For particular material and initial size the ball size must be optimized. Please refer the link below and see if it

23/12/2013#0183;#32;Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: ''Ball milling is a method used to break down the solids to smaller sizes or into a powder. A

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

End Mill Sizes Inch, Metric, And Micro; Size. Decimal. Category . Size. Decimal. Category . Size. Decimal. Category . Size. Decimal. Category. Micro . Micro. Micro. 7/16quot; Inch. Micro. Micro . Metric. 29/64quot; Inch. Micro. Micro . Micro. 15/32quot;

WhatsApp)

WhatsApp)