(PDF) A comparison of wear rates of ball mill grinding

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

WhatsApp)

WhatsApp)

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

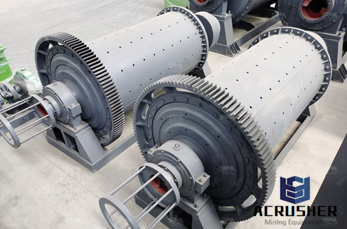

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Milling media and grinding media are most popular in grinding processes that involve ball milling equipment such as planetary milling jars and planetary mill machines. Milling balls made of steel and ceramic are our most popular materials. MSE Supplies provides quality, durable, and high performance milling media. We urge our customers to select the best grinding media to fit their needs and

ball mill grinding media selection. The type of mill also can affect the selection of grinding media Ball Mills use very large media while Attritors employ media ranging in size from 18 to 1 Horizontal mills require much smaller media as small as 005 mm to 2 mm To read detailed specs and submit a quote click here for our metallic mediaor

#0183;#32;Steel ball grinding media are used in tower mills, Isa mill, rotary mills, semiautogenous grinding (SAG) mill. Plastic Grinding Media. Plastic ball mills are made from high quality and special resin. Plastic ball mills can be used as a substitute for metallic ball mill

ball mill grinding media selection. The type of mill also can affect the selection of grinding media Ball Mills use very large media while Attritors employ media ranging in size from 18 to 1 Horizontal mills require much smaller media as small as 005 mm to 2 mm To read detailed specs and submit a quote click here for our metallic mediaor

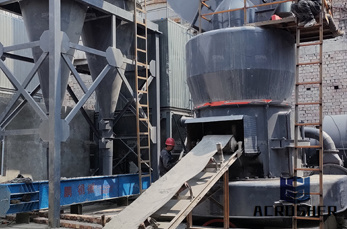

Ball Mill Grinding Circuit. An improved control strategy for ball mill grinding an improved control strategy is proposed to control ball mill grinding circuits for energy saving and pollution reduction a two layer optimization architecture combined by particle size chat now Operating Comminution Circuits Without Grinding Media The

Improved wear resistant materials can be installed for grinding media, especially in ball mills. Grinding media are usually selected according to the wear characteristics of the material. Increases in the ball charge distribution and surface hardness of grinding media and wear resistant mill linings have shown a potential for reducing wear as well as energy consumption.

Improved grinding media for ball mills industrial improved wear resistant materials can be installed for grinding m. Size Reduction Equipment | Paul O. Abb#233; Paul O Abb#233; Equipment Company is a manufacturer of new Size Reduction Equipment such as Ball Mills, of fine grinding solids from the grinding media.

grinding aids for ball mills industrial efficiency. In addition the ball mill noise emission of the second chamber the coating effect in it as well as the use of grinding aid can also be significantly reduced Another effect is a lower grinding heat and therefore a reduced cement temperature after the ball mill The company is currently also focussing on the processing of industrial minerals

NOTE: With media load at 50%, voids are created equal to 20% of cylinder volume. These voids are filled when product is loaded into the mill. Mills can be loaded by volume or by weight based on products bu lk density. Type of Grinding Media Two types of grinding media

#0183;#32;According to Bond (1954), the grinding efficiency of a mill depends on the ball mill diameter, size of the media and mill speed. Ball mills with different length to diameter ratios for a particular power rating will produce different material retention times.

Diameter depending on the material, ranging from mm to 2 mm for small media mills, up to 1/8 to 1 for traditional Attritors and up to #189; to 2 for ball mills Composition metallic grinding media like carbon steel, forged steel, stainless steel or chrome steel grinding balls are best for some applications, while others require nonmetallic media made of alumina, ceramics, glass, silicon carbide, zirconium oxide

Ball Mill Grinding Circuit. An improved control strategy for ball mill grinding an improved control strategy is proposed to control ball mill grinding circuits for energy saving and pollution reduction a two layer optimization architecture combined by particle size chat now Operating Comminution Circuits Without Grinding Media The

Grinding Media Of Ball Mill Used For Cement Manufacturing. In order to reduce the manufacturing costs for cement, it is very important to optimise the existing mill installations as far as the grinding process is concerned and also to use high quality spare parts and consumables like grinding media ball mills are predominantly used machines for grinding in the cement industry although ball mills.

Upgrade your milling efficiency with ceramic grinding media balls. If you need media to crush materials in a ball mill, you want durable, dense, and impactresistant ones. At the same time, they shouldnt abrade your equipment from within during the cylinder rotation process.

Ball mill hardened LeadAntimony media 100 pcs 1/2 inch 1/2quot; leadantimony non sparking grinding media great for black powder and other combustible chemical..

WhatsApp)

WhatsApp)