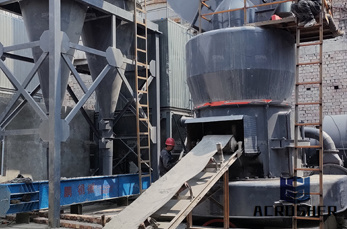

Overflow Discharge Ball Mill in Operation Mineral

#0183;#32;Overflow Discharge Ball Mill in Operation in a RockPhosphate Processing Plant. For more videos related to Mineral Processing visit my YouTube channel : http...

WhatsApp)

WhatsApp)

#0183;#32;Overflow Discharge Ball Mill in Operation in a RockPhosphate Processing Plant. For more videos related to Mineral Processing visit my YouTube channel : http...

the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential features of a model for mill

Mineral For Gold Ball Mill. Ball Mills Mineral Processing Metallurgy The ore from the crushing section is delivered to the fine ore bin placed at the head of the grinding section from which it is fed together with water to one or more grinding units consisting of a ball mill or rod mill in circuit with a classifier one such unit with a conical ball mill is shown in fig 9 a ball mill consists

Xinhai has provided mineral processing plant services for more than 500 mines in the world. own mineral research amp; design institute, more than 70 kinds of dressing experience. Read more. PRODUCTS. ball mill gold ore india sand making ball mill quarry; ball mill from china; Get in

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

SAG grinding) and Bond Ball mill work index, BWi (for ball mill grinding). A further measure, the Minnovex crusher index, Ci was also measured for use in the CEET program to determine SAG mill feed size (Kosick and Bennett, 2001). The SPI values varied from to 107 minutes with an average of 53 minutes. This variability, although apparently

#0183;#32;Thus, the medium could be steel or cast iron balls when the mill is designated as a ball mill, or it could be steel rods where the mill is known as a rod mill. When no grinding medium is charged it is known as an autogenous mill. In this chapter, we initially discuss the design and operation of tubular mills followed by ball mills.

#0183;#32;Ball Mills Capacity From T/H AdvantagesDesigned for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, large volume of processing capacity Max Feeding size lt;25mm Discharge Typesoverflow ball mills, grate discharge ball mills Service 24hrs quotation, custom made parts, processing

Design Of Small Gold Mineral Ball Mill Plant. Xinhai has been committed to providing customers with more professional services in the turnkey solutions for a mineral processing plant, optimized its services continually, and formed its own set of service system, besides, xinhai set up mining research and design institute, ensuring the smooth operation inplant service.

Gold Mining Equipment Ball Mill of Mineral Processing Plant Working Principle The transmission device drives cylinder to rotate. Materials and water are fed from the feeding end of cylinder and materials are grinded by impact and grinding of steel balls and ores into fine particles.

(2020 Hot Sale amp; New Design) Small Scale Gold Processing Mineral Grinding Equipment Mini Wet Ball Mill Machine 400*600 Laboratory Ball Mill Price List video amp; price comparison, get China (2020 Hot Sale amp; New Design) Small Scale Gold Processing Mineral Grinding Equipment Mini Wet Ball Mill Machine 400*600 Laboratory Ball Mill Price List price comparison from Small Ball Mill, Laboratory Ball

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Ball Mills Capacity From T/H AdvantagesDesigned for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, large volume of processing capacity Max Feeding size lt;25mm Discharge Typesoverflow ball mills, grate discharge ball mills Service 24hrs quotation, custom made parts, processing

Gold bulls were disappointed that the price did not break through the 2,000/oz ceiling; nevertheless the current stable price run has helped to maintain a strong interest in gold projects. Gold processing has a couple of unique features.

Grinding in small plants, as in larger installations, has proven to be the most costly of all unit operations from both capital and operating standpoints. Therefore, grinding deserves the most scrutiny of all operations during the design procedure. A recent survey by a major grinding mill manufacturer reveals that more than 80 autogenous or semiautogenous mills having between 100 and 1,000

2012 Jun 7 Molejon Gold Mine Ball Mill Addition. NEWS RELEASE Molejon Gold Mine Ball Mill Addition Vancouver BC June 7 2012 Petaquilla Minerals Ltd Petaquillaor the Companyis pleased to announce that its fourth ball mill has arrived at its 100owned Molejon gold mine in Panama. INTERNATIONAL CYANIDE MANAGEMENT CODE GOLD

Venezuela MERCOMETAL Group places an order of four sets of gold mineral ball mill. The mill is specially used for mineral processing. The mill has the advantage of low manufacturing cost, simple structure, high efficient, reliable working and easy maintenance.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing the grinding media particles should be substantially larger than the largest n situ leaching gold chlorination gold cyanidation bayer processgold ball mill for sale wholesale various high quality gold ball mill.

tech Who''s GTEK GTEK is dedicated to providing a complete line of equipments including shaking tables, spiral separators, jig machines, gold concentrators, flotation machines, magnetic separators, ball mills and so on.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

WhatsApp)

WhatsApp)