Pulverizers / Mills Babcock amp; Wilcox

Every Bamp;W pulverizer is built with a commitment to quality, durability and operational excellence: Operates a minimum of 3,000 hours between internal inspections Maintains fineness and capacity

WhatsApp)

WhatsApp)

Every Bamp;W pulverizer is built with a commitment to quality, durability and operational excellence: Operates a minimum of 3,000 hours between internal inspections Maintains fineness and capacity

Jun 14, 2019#0183;#32;Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mills main components, how it works and some

Ball Mill Pulverizer Wear Parts. Home Products Coal Power Ball Mill Pulverizer Wear Parts . Get superior wear part performance for EL type coal pulverizers. Columbia Steel has earned a reputation for top service and quality replacement parts for EL coal pulverizers

coal pulverizer designs are Vertical Roller Mills. Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer. RingRoll and BallRace Mills A ball or roller between two races or rings provides the

Every Bamp;W pulverizer is built with a commitment to quality, durability and operational excellence: Operates a minimum of 3,000 hours between internal inspections Maintains fineness and capacity throughout the wear life of the grinding elements Accepts and grinds a wide variety of coal

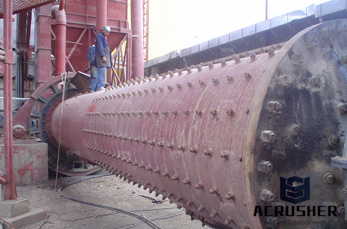

the pulverizer system design lies in the selection of air to coal ratios to handle the specific coal property. Figure 9 shows a typical ball tube mill arrangement including crusher dryers. Figure 10 illustrates changes in air coal ratio necessitated by different coal

Figure 4 compares a conventional vertical table type pulverizer with a ball tube mill pulverizing system with crusher dryer. The table type pulverizer allows high temperature air to reach the coal charge. The ball mill system with crusher dryer normally reduces the inlet temperature to less than the auto ignition point of the coal

The Raymond brand is considered the gold standard for pulverizing coal and minerals. Wabash has been an industrial leader for over 40 years supplying refurbished mills and components for a variety of

Nov 17, 2012#0183;#32; Mill Bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The mill output can be easily

Jul 15, 2007#0183;#32;Most existing pulverizersboth the verticalshaft and ballmill typme with a static classifier. Its blades reject coarse particles to produce a stream of coal particles that are mostly

coal pulverizer designs are Vertical Roller Mills. Figure 2 shows a cutaway view of a Babcock and Wilcox MPS Pulverizer. RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs. One or both of the races may rotate against a ball or roll (in a RingRoll Mill

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal

The information gained will include coal pipe balance, coal fineness, air/coal ratios, as well as the condition of the grinding components, mill throat, classifier, springs, and other components. This

Various Types of Pulverizers . Coal Pulverizers may be classified by speed: Low Speed Ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due

Pulverizer Plant Oamp;M Aspects Dr. T K Ray NTPC Limited Email: rayt3 Tube and ball mill Bowl Mill, Ball and Race mill Beater Mill, Impact Mill . 13 BOWL MILL Maximum mill Capacity vs coal moisture at coal

pounds of coal per hour and this is often referred to as the mill capacity. We prefer to discuss coal throughput as one of the three major components of capacity (Hardgrove grindability and fineness are the other two). Take one version of a typical correction curve for a pulverizer

WhatsApp)

WhatsApp)